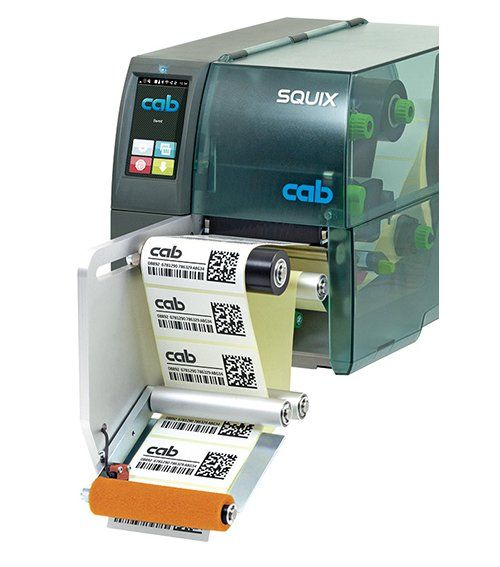

SQUIX 4/Applicators

Labeling in real time

Applicator S1000

A S1000 assembled to a SQUIX peel-off printer provides a cost-effective solution if operated semi-automatically or integrated in vertical orientation in production lines. A stroke cylinder applies the labels to products.

Applicator S3200

A S3200 assembled to a SQUIX peel-off printer provides a cost-effective solution if operated semi-automatically or integrated in production lines. Printed labels are applied to products automatically. For this purpose, labels are set 45° to 95° to the horizontal by a rotary cylinder and move towards products by means of a a short-stroke cylinder.

Long service life: The ball-bearing guides are low-wearing.

Products of different heights: can be labeled by means of a stroke cylinder. Various stroke lengths are provided.

Compressed air regulation unit: Micro filters prevent from contamination. Regulating the pressure ensures a permanent good labeling quality.

Highly-reliable processes: The supporting air, intake air and stroke speed may be adapted. If sensitive products and packagings are in use, the pressing force can be reduced to less than 10N (1 kg). To prevent intake ducts from contamination, they get purged after any labeling.

Label sizes: Labels 25 to 176 mm wide and 25 to 200 mm high can be applied.

Pre-dispensing button: to verify a labeling process. By pushing the button once, a label is printed and transferred to the applicator. By pushing the button once more, labeling is triggered.