LX-600T / LX-600DT

Label Solution for the Real World

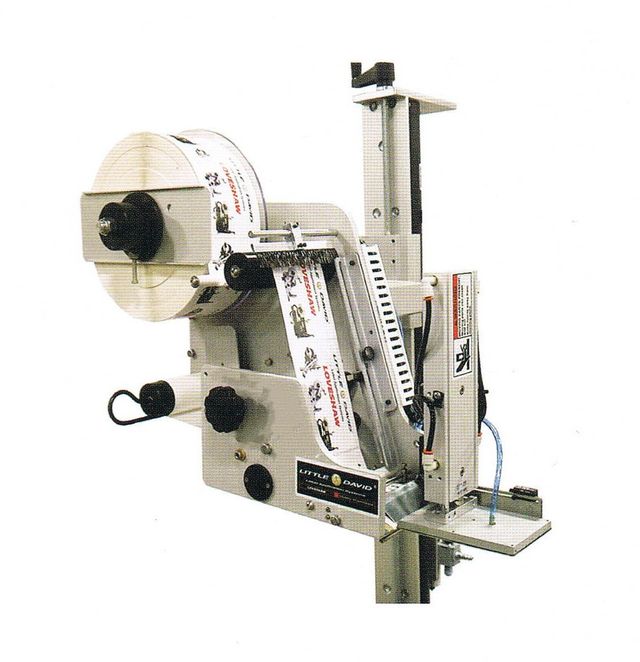

The LX-600T and LX-600DT label applicators are built for demanding production environments where reliability, accuracy, and ease of use matter most. The LX-600T is ideally suited for automatic tamp applications using preprinted labels on both uniform and randomly sized cases, making it a flexible choice for high-throughput operations. The LX-600DT extends that capability by supporting both dual tamp and corner wrap applications, offering greater versatility for complex labeling requirements.

Operators benefit from simple, intuitive controls powered by a rugged industrial Allen-Bradley PLC paired with an HMI touchscreen. This setup allows for fast configuration changes, easy operator adjustments, and minimal training time, helping teams get up and running quickly while reducing errors and operational delays.

The LX-600T features a random stroke applicator capable of applying labels to varying case sizes within its reach, with an effective stroke length of 6½ inches. High-quality components, including Allen-Bradley controls and SMC pneumatics, improve uptime and ensure parts are readily available and familiar to maintenance personnel.

A tool-less mounting stand allows the labeler to be easily rotated for standalone operation or seamless conveyor integration. Customizable applicator pads further enhance adaptability, ensuring consistent, accurate label placement across a wide range of packaging applications and production line configurations.